The field of dental implants has undergone significant advancements in recent years, with one of the most important developments being the improvement of implant materials. The success of dental implants heavily depends on the materials used, as they must not only withstand the mechanical stress of daily use but also integrate seamlessly with the body. As technology continues to evolve, dental implant materials are becoming more biocompatible, durable, and customizable.

Let’s explore emerging trends in implant materials, focusing on biocompatibility and the innovations that are pushing the boundaries of what's possible in implantology.

The Importance of Biocompatibility

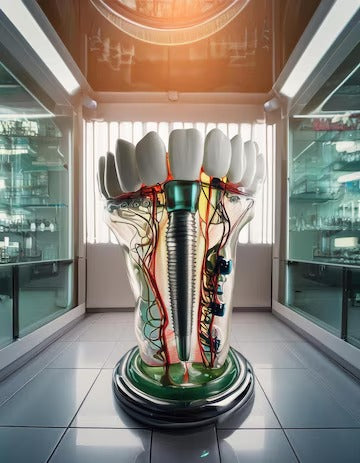

Biocompatibility is the foundation of dental implant success. It refers to the ability of a material to perform its intended function without causing harm or adverse reactions in the body. For dental implants, biocompatibility ensures that the material integrates with the jawbone through a process known as osseointegration. Titanium has long been the gold standard in implant materials due to its excellent biocompatibility, corrosion resistance, and strength. However, recent advancements have introduced new materials that are challenging titanium's dominance.

1. Zirconia: The Ceramic Alternative

Zirconia implants, made from a high-performance ceramic material, are gaining popularity due to their excellent biocompatibility and aesthetic appeal. Unlike titanium, zirconia is white, making it an ideal choice for patients seeking a more natural-looking solution, especially in the anterior (front) regions of the mouth. Zirconia’s chemical composition allows it to bond well with bone tissue, making it an effective option for osseointegration.

One of the biggest advantages of zirconia over titanium is its lack of metallic appearance, which is a common concern for patients undergoing implant procedures in visible areas. Zirconia is also highly resistant to corrosion and plaque buildup, making it an excellent choice for patients with sensitivities to metals. However, zirconia implants are typically more brittle than titanium, which may limit their use in certain situations where strength is paramount, such as in molar replacements.

2. Titanium-Alloy Implants: Enhancing Strength and Flexibility

Titanium alloys, particularly those that incorporate elements like zirconium or niobium, are being developed to enhance the properties of traditional titanium implants. These alloys are stronger and more flexible than pure titanium, offering an improved balance between strength and biocompatibility. Titanium alloys are often used in high-stress applications, such as full-arch restorations or cases where implant failure could lead to complications.

The latest generation of titanium alloys is also more resistant to corrosion, reducing the risk of implant failure due to environmental factors. The addition of zirconium to titanium alloys, for example, enhances the material’s aesthetic properties by reducing the possibility of a visible metallic appearance, particularly in the gum tissue. These developments provide a more versatile solution for both functional and aesthetic requirements in dental implants.

3. Bioactive Materials: Promoting Healing and Bone Growth

Bioactive materials are a new frontier in dental implant technology. These materials, which include bioceramics and composites, not only provide mechanical stability but also actively promote biological processes like bone regeneration and tissue healing. Some bioactive materials release ions that stimulate osteoblast activity (bone-forming cells), accelerating the integration of the implant with the jawbone.

For example, hydroxyapatite (HA), a naturally occurring mineral form of calcium apatite, is being used to coat titanium implants to promote better osseointegration. HA coatings mimic the composition of human bone, providing a more natural environment for bone cells to attach and grow. Recent innovations in bioactive materials include self-healing coatings, which help prevent infection and inflammation around the implant site, contributing to faster healing and a reduced risk of complications.

4. Nanotechnology: Enhancing Surface Characteristics

Nanotechnology is revolutionizing the way implant surfaces are designed. By manipulating materials at the nanoscale, researchers have developed coatings that improve the biological response to implants. Nanostructured surfaces can enhance osseointegration by promoting better attachment of bone cells to the implant surface.

For instance, nanoparticle coatings can increase surface roughness, which has been shown to improve the bonding of the implant to the bone. This can result in quicker healing times and better long-term stability. Additionally, nanomaterials can also be engineered to release therapeutic agents, such as antibiotics, to prevent infection around the implant site. The ability to fine-tune surface properties through nanotechnology opens up new possibilities for dental implants with superior performance.

5. Customizable Implants: Tailoring Materials to Patient Needs

One of the most exciting trends in dental implant materials is the shift toward personalized, patient-specific implants. Advances in 3D printing and computer-aided design (CAD) allow dental professionals to create customized implants that are perfectly suited to each patient’s unique anatomy. This approach minimizes complications and improves both the functional and aesthetic outcomes of implant procedures.

In terms of materials, this customization can extend to the combination of materials used. For example, a dentist might choose a titanium core for its strength, while utilizing a bioactive coating to promote faster healing and bone growth. Customization also allows for adjustments to implant shapes, sizes, and surface textures based on a patient’s specific needs, leading to more precise and effective treatments.

Looking Beyond Biocompatibility: The Future of Implant Materials

While biocompatibility remains the cornerstone of dental implant success, the future of implant materials is about more than just compatibility with the human body. Future trends point toward the integration of additional functionalities, such as:

- Antimicrobial Properties: The development of materials that actively resist bacterial growth to prevent peri-implantitis and other infections.

- Smart Implants: Incorporating sensors into the implants that monitor bone health and signal when maintenance or replacement is needed.

- Sustainability: The move towards more eco-friendly materials, such as biodegradable or recyclable implant options, as sustainability becomes an increasingly important factor in healthcare.

Dental implant materials have come a long way from the days of simple titanium implants. Emerging trends in materials, such as zirconia, bioactive coatings, nanotechnology, and 3D printing, are opening up new possibilities for implantology, improving patient outcomes, and enhancing the patient experience. Biocompatibility remains a key consideration, but with innovations that go beyond basic integration, dental implants are becoming even more reliable, functional, and patient-friendly. For dentists looking to stay ahead of the curve, keeping an eye on these emerging trends will be essential for providing the best possible care and expanding the possibilities of dental restoration.

At Dental Valley, we stay at the forefront of emerging trends in implant materials, focusing on biocompatibility and advanced solutions that prioritize patient safety and long-term success. Our range of cutting-edge implants is designed with the latest materials that not only ensure optimal integration with bone tissue but also enhance durability, comfort, and aesthetics. We are committed to providing dental professionals with access to the most innovative, scientifically backed materials, allowing them to offer patients the best possible care. By continually advancing our product offerings, we empower practitioners to deliver superior results while maintaining the highest standards of patient well-being and satisfaction.